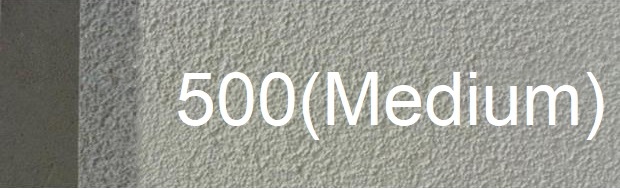

Uni-Trowel 500 - 15L acrylic texture

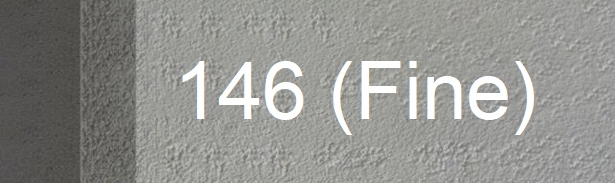

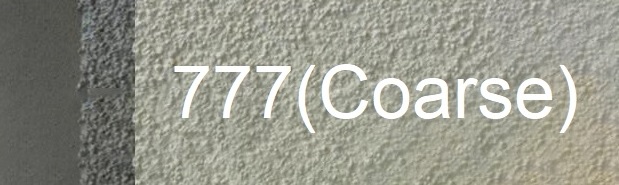

Medium Texture 500

Colour

The pigmentation is completely integrated during the manufacturing process, which means colour through the entire film thickness. Applied Finishes are available in a practically unlimited range of full colour to pastel shades.

This texture product can be tinted or colour matched to almost any colour.

NB: Deep tone colours are not always suitable for exterior application

Biological Resistance

Resistance to attack from bacteria and fungi is provided. This product being a water based acrylic system offers safe handling and low toxicity properties. Dirt, grime and dust on the surface of coatings will act as seed beds for bacterial attack, therefore cleaning and maintenance of your coating is essential to hinder bacterial and fungal attack.

Fire Resistance The full Unitex coating system when subjected to the Early Fire Hazard Tests – Australian Standard AS1530.3:1999 meets the strictest standards.

Water Resistance

The coating, even at exceptionally high build, is formulated with a water vapour permeability factor to allow water vapour from the substrate to leave unhindered and to rainproof the exterior. Rising damp and elevated levels of moisture in the substrate will damage, and possibly delaminate, the surface coating. Please ensure that damp coursing the substrate is in place and prior test moisture content with a moisture meter (maximum 12% WME is allowed) (Builder responsibility).

Usage Guide

|

Step 1: Prepare walls & Install angles Step 2: Apply render, screed & float Beach Render for Brick & Masonry Aero Render for AAC & Hebel Panels Dry Poly Render for Blueboard & Fibre Cement Sheets Wet Polymer Render for Blueboard & Fibre Cement Sheets Base Board 20kg Render for Polystyrene Panels Step 3: Apply texture at 1mm & finish with float

Step 4: Apply paint using roller or brushes

|

Contact us to get specified

Our Render, Texture & Paint sales team on 02 8775 8617 or email rtp@humebuildingproducts.com.au.

Check out other substrate render systems

AAC Render System | Blueboard Render System | Brick & Masonry Render System | Concrete Render System | PVC Render System | Polystyrene Render System